We have made it possible to centrally manage the internal equipment with a warehouse and equipment management system. By using RFID, it is possible to improve work efficiency and prevent human error such as equipment loss, thus ensuring the safety of the construction site and warehouse.

Overview

Customer Business

- Manufacturing Industry (listed on Tokyo Stock Exchange’s First Item)

Scope of work

- Understand the problem

- Definition of requirements (proposal of specification, proposal of specification)

- Design (user interface design, system design, infrastructure design)

- Development System

- Operation and maintenance

Development period

- 18 months

Achievements

- We were able to reduce human error and standardize inventory management practices.

- We were able to reduce costs and cut labor costs by 15%.

- Accelerate decision making in each department and improve the performance of the entire organization

Referral context / Client's problem

- Overly dependent on workers and craftsmen

・ Unable to share information and knowledge

・It is easy to get confused because you do not know when to buy

・Need the help of experienced craftsmen - Want to improve safety at construction sites (high-pressure processing sites)

・Lots of tools and frequent occurrences, but not being able to manage them - Want to implement work style reform

・ Need to speed up management, preparation and purchasing decisions

Request/development details

Develop a system that can manage warehouses and equipment consistently

Our solutions

- Build a warehouse and equipment management system to centrally manage in-house equipment.

- As a result, three improvements can be made: work efficiency, time reduction, and work accuracy improvement.

The process to be able to prepare and test equipment using RFID

As a result, three advancements can be realized: easy validation, work efficiency, and time reduction.

Overview of the development system

An inventory management system consists of the following three components

- Registration (inventory registration/receipt): RFID Link

- Ready (preparing for receiving and shipping): RFID Link

- Field (on-site device management): RFID link

List of functions

- Inventory Control

- Repair Management, Disposal Management, Lease Management

- Purchasing / Order Management

- Delivery, warehousing and warehousing management

- On-site support tools (manage budgets, create equipment lists, test equipment for each stage)

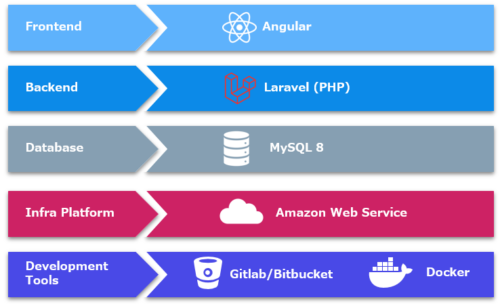

Suggested technology

- React/Angular

Interpretation of React/Angular UI’s pseudo-library DOM be great. It is able to eliminate unnecessary rendering at high speed with SPA. - PHP

PHP is a very flexible language with a simple syntax, rare limitations and uncomplicated to develop, maintain in the future. - Laravel

It is the most accustomed framework for Laravel PHP and easy to develop because there are many plug-ins required for development, and it is easy to maintain in the future because of the small amount of description. - MySQL

As the world’s most popular open source database, providing high performance, high reliability and ease of use.